Precision Carbide&HSS Component Manufacture

![]() +86 13709654005

+86 13709654005 ![]() ivy@hg-jingmi.com

ivy@hg-jingmi.com

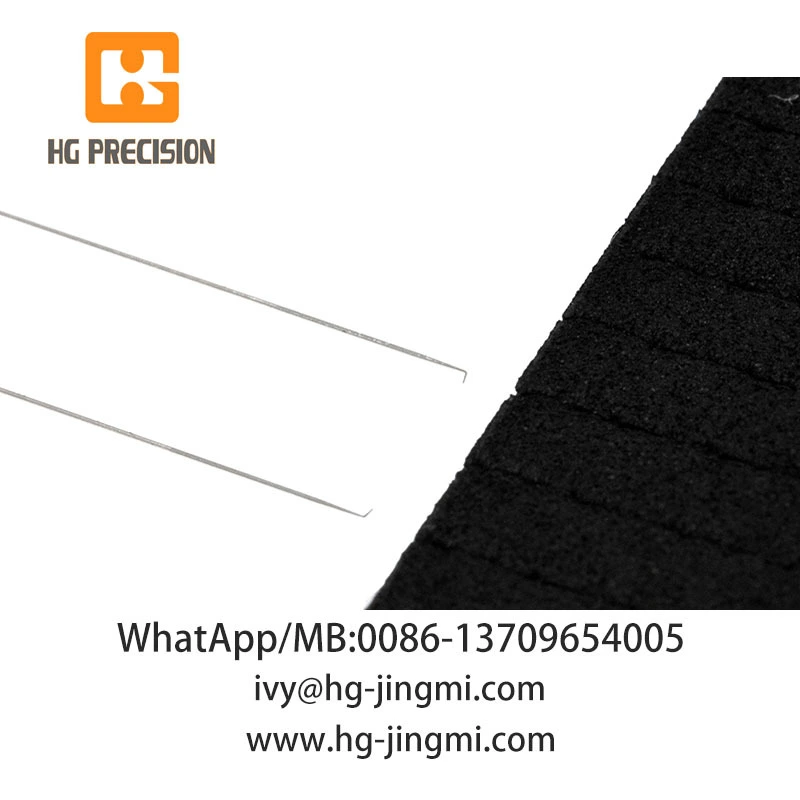

Tungsten Probe Pins With Sharp Edge Bening-HG

Material: Tungsten

Quality Control: 2.5D, 3D, high tester, hardness tester

Shipment by: DHL, OCS, UPS, FedEx and so on

Lead time: within 18-22days, urgent schedule is possible for not complex precision component.

We provide comprehensive customization support and work closely with customers to meet design drawings and system matching requirements.

Tungsten Probe Pins With Sharp Edge Bening can be used for shaving, peeling, cutting, and picking up various small objects, as well as for detecting, marking, classifying, and cleaning in microscopy, experimentation, research, sample preparation, and assembly applications.

Advantages:

- Strong yet precise enough to lift fragile lamella without breakage.

- High stiffness and elasticity.

- exceptional precision and endurance.

- High hardness and elasticity prevent bending or tip deformation.

Customizing the tip shape can also improve contact and reduce false signals.

- High quality material control: We process tungsten to ensure stable and high-purity raw material quality.

- Ultra precision machining: The validated tip control machining tolerance is as low as 0.001mm.

- Comprehensive and strict inspection: Each tip undergoes a comprehensive inspection before packaging, including but not limited to optical inspections such as 3D projection.

In practical production applications, non-destructive testing can be achieved to protect sensitive chip structures.