Precision Carbide&HSS Component Manufacture

![]() +86 13709654005

+86 13709654005 ![]() ivy@hg-jingmi.com

ivy@hg-jingmi.com

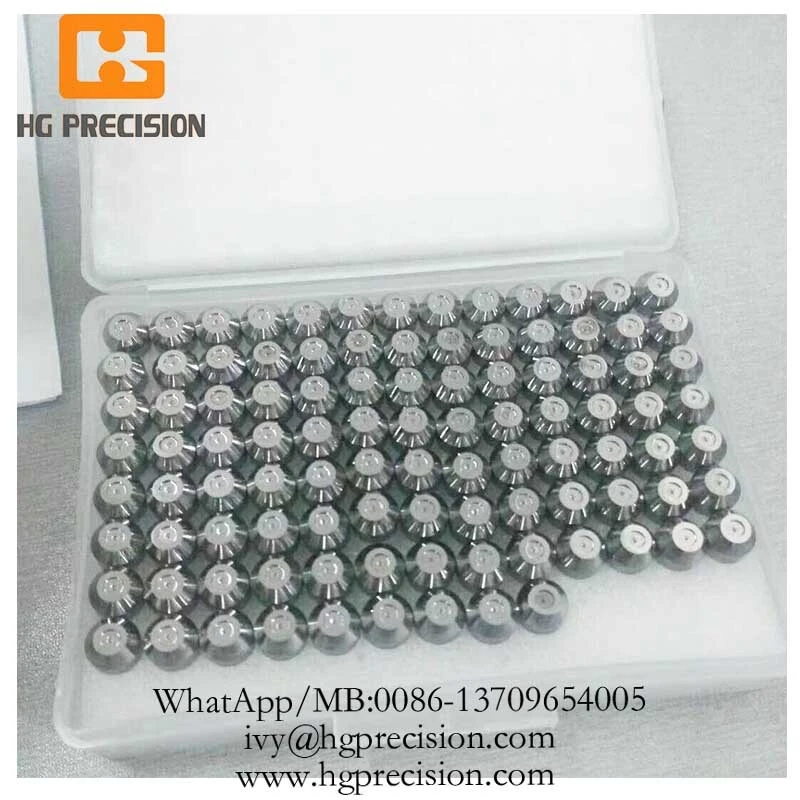

Special Carbide Nozzle

Precision Nozzles For Fluid Dispensing Equipment

We provided dispense valve assemblies, tugnsten carbide nozzles, tungsten carbide ball-end needle, carbide seat and anti-abrasive hard-coated needle, gasket, shaft.

HG Precision tungsten carbide resist high temperatures, withstand high pressure, excellent corrosion resistance and guarantee long life and high repeated accuracy.

The surface treatment is TiCN, TiN, Aitain, Ticrn Nitriding, Black Oxygened, black coating etc available

Processing technology: die polished, plating titanium, lettering, wire EDM, electro-discharge machining, titanize, heat treatment, fast wire cutting, slow wire cutting, heat annealing, sintering

Our products including the following:

Powder metallurgy dies:1.Ferrous metal moulds: like gear finished die,sizing die,automobile parts,motor driven tool parts,etc. 2.Magnaglo moulds:like E shape dies,U shape dies,PM shape dies,G shape dies,etc.

Kinds of tungsten carbide TF products:

1.Tungsten carbide nonstandard dies:like cold heading dies,battery dies,carbide blanking dies,tretching die,etc.

2.Tungsten carbide wear parts:carbide rollers,carbide gauge.

Our company can accept all trading manners, e.g EXW, FOB, CIF, DDP, DDU.etc

We can also accept any kinds of payment terms, such as TT, L/C, D/P, O/A.etc

Nordson Asymtek is used in printed circuit board (PCB) assembly

Nordson Asymtek has been an innovator and leader in advances in dispensing technology for printed circuit board assembly (also known as surface Mount (SMT)) -- from early time pressure pumps to spiral valve systems to today's jet technology and closed-loop process control -- offering more choices in balanced speed, volume control, precision, and price.

Use bottom filling glue to reduce fault protection

Many large components on a mobile device board, such as cascading packaging (POP), ball-gate array (BGA), and chip level packaging (CSP), require bottom-filling technology to prevent breakouts.These components are very tightly distributed.Non-dispensing area (KOZ) is an important parameter for identifying good bottom filler dispensing: the small bottom filler edge at the edge of the component must be densely distributed.A small amount of bottom filler glue must be applied near the component, which requires the dispensing system to deliver the tiny amount of glue to the exact location.In addition, productivity is critical, so jet speed determines productivity.