Precision Carbide&HSS Component Manufacture

![]() +86 13709654005

+86 13709654005 ![]() ivy@hg-jingmi.com

ivy@hg-jingmi.com

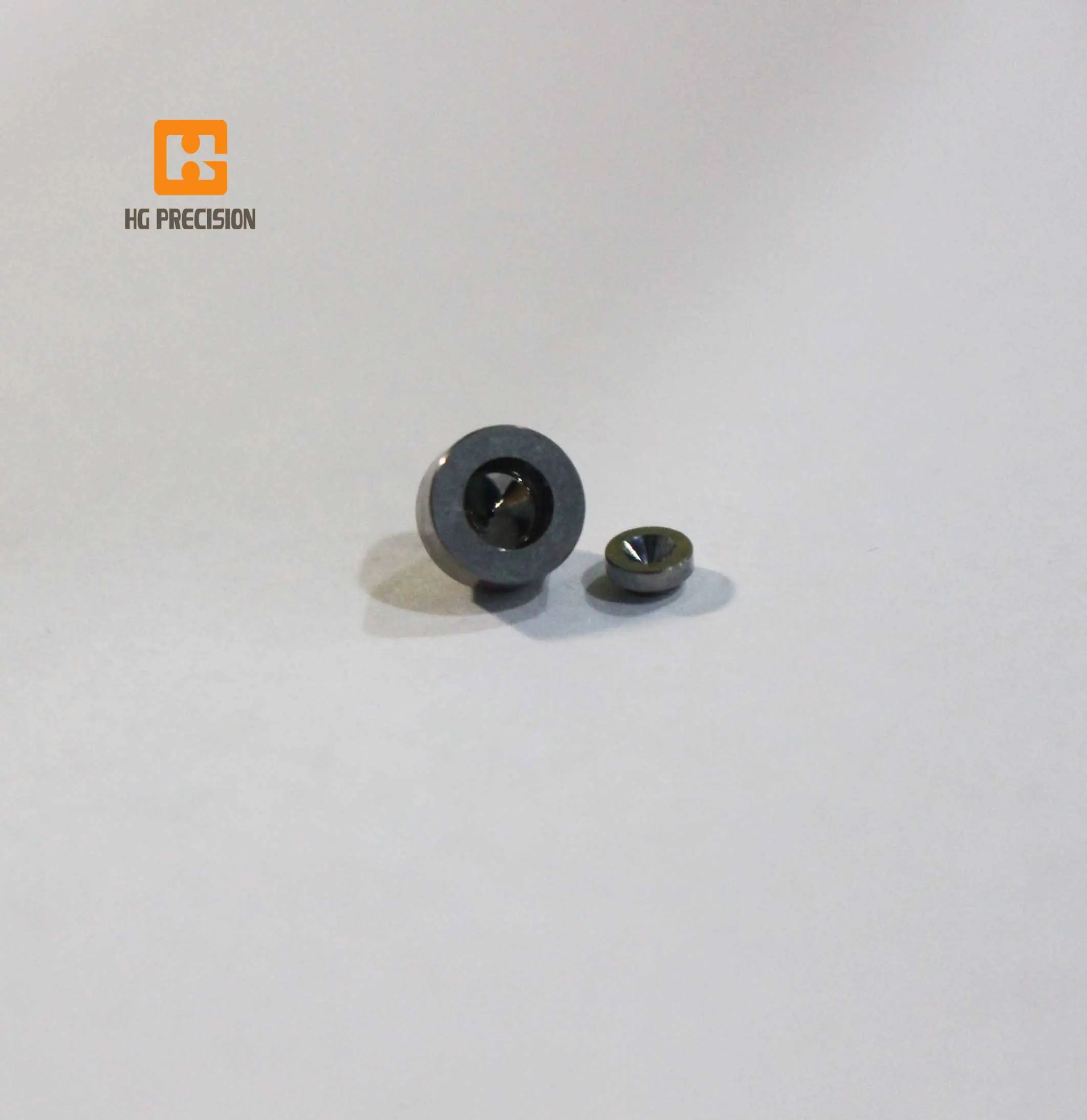

Precision Carbide SMT Nozzle

Precision Carbide SMT nozzle

The nozzle of the dispensing machine is to point a special glue in the position where the patch is needed on the PCB board in advance to fix the patch elements, and then undergo wave soldering after curing.Dispensing is automatic according to the program, its working principle adopted the form of pneumatic auxiliary rubber valve control, use the match to reach the ideal degree.The applied industries mainly include the electronic industry, lighting industry, home appliance industry and other fields. The automatic operation mode improves the production efficiency and product quality.

Dispensing machine nozzle classification industry to glue control equipment called many, dispensing machine nozzle, filling machine, coating machine, dropping machine and so on.According to our company's cognition of the industry and many years of industry experience, with reference to the summary of the industry in Europe, the United States and Japan, this kind of equipment is summarized as the nozzle of dispensing machine and divided into three or two categories:

1. Nozzle of single-component dispensing machine

Dispensing controller

Nozzle of desktop dispensing machine

Nozzle of floor type dispensing machine

2. Nozzle of two-component dispensing machine

Nozzle of semi-automatic two-component dispensing machine

Nozzle of automatic two-component dispensing machine

3. Nozzles of non-standard dispensing machine ordinary

Normally type:

1. Nozzle of controller-type dispensing machine

It includes nozzle of automatic dispensing machine, nozzle of quantitative dispensing machine, nozzle of semi-automatic dispensing machine, nozzle of digital display dispensing machine, nozzle of precision dispensing machine, etc.

2, desktop dispensing machine nozzle

Including desktop dispensing machine nozzle, desktop triaxial dispensing machine nozzle, desktop four axis point glue machine nozzle, or desktop type automatic dispensing machine nozzle, 3 axis line dispensing machine nozzle, long nozzle glue, glue dispensing machine nozzle, draw more dots glue machine nozzle, turn marks glue machine nozzle, horn glue dispensing nozzle, cell phone buttons machine nozzle, cabinet dispensing machine nozzle, etc.

3. Nozzle of semi-automatic dispensing machine

It includes nozzle of microcomputer precision dispensing machine, nozzle of led digital display dispensing machine, nozzle of automatic back suction dispensing machine, nozzle of code drawing cycle dispensing machine.

Automatic type

1, floor type double liquid dispensing machine nozzle.

2, spray type automatic dispensing machine nozzle (this dispensing machine nozzle adopts spray valve, on-line operation, mainly used for PCB board three anti-paint spraying, dust, moisture, insulation).

3, the conductive glue automatic dispensing machine nozzle (this dispensing machine nozzle and the common dispensing machine nozzle difference is that the point out of the conductive adhesive cutting surface is triangular distribution, mainly used for electromagnetic shielding dispensing).

4. The nozzles of the phosphor injection dispensing machine (the nozzles of the dispensing machine are mainly used in the led industry).

Double y type

The nozzles of such dispensing machines include two moving platforms, while the nozzles of traditional dispensing machines generally contain only one moving platform.Generally, each sports platform can be equipped with more than 5 dispensing heads to achieve a leapfrog improvement of dispensing efficiency.It is suitable for precise dispensing of LCD and liquid crystal module, and is most widely used in liquid crystal screen field such as mobile phone liquid crystal screen and PDA.

Non-standard class

That is, according to the customer's product process of some special requirements, customized, this kind of dispensing machine nozzle is often high development cost.

Uv dispensing machine nozzle

1. Introduction to the nozzle of the ultimusv dispenser:

Instead of the operator's guesswork, the amount of fluid applied to the parts is adjusted by the use of air pressure and a microprocessor based timing device.The efd's pneumatic dispensing system eliminates variability in the traditional dispensing process.

2. Advantages of the ultimusv dispenser nozzle include:

High productivity and pass pass rate.

Strong process control.

Excellent product quality, reliability and elegant appearance.

Lower rework rate and less defective product rate.

No waste or confusion.

Training was simplified for new staff.

The ultimusv high precision dispensing machine nozzle takes the precision and consistency of dispensing to a new level, enabling precise control of adhesives that are easy to viscosity, such as:

A two - component epoxy adhesive whose viscosity varies with time.

The viscosity changes with the temperature of uv curing adhesive.

3. Nozzle characteristics and advantages of ultimusv dispenser:

1, whether the viscosity of the adhesive changes or not, the glue point is always constant.

2. Electronic control of dispensing time, air pressure and vacuum ensures highly accurate dispensing effect.

3. The air pressure can be adjusted automatically with the change of fluid viscosity.

4. The unique "setitandforgetit" technology makes the dispensing operation simpler, with each fluid only needing to be programmed once for each dispensing.

5. Display all dispensing parameters at the same time, greatly simplifying the process control.

Nozzle of led dispenser

Led special equipment, dedicated to the production of white led phosphor in the process of gluing.

Nowadays, the nozzles of led dispensing machines can be divided into two categories: one is air pressure type, and the other is metering type.

Because the amount of led phosphor requires to be very precise, and the amount of air pressure will vary with the size of the air pressure, so the nozzle of the air pressure dispensing machine cannot hide from the needs of the led industry, so it is not called the nozzle of the led dispensing machine.Led industry USES the basic are metering type, his glue quantity accuracy can reach 10,000, can meet the led phosphor dispensing glue, this is called the real led dispensing machine nozzle.