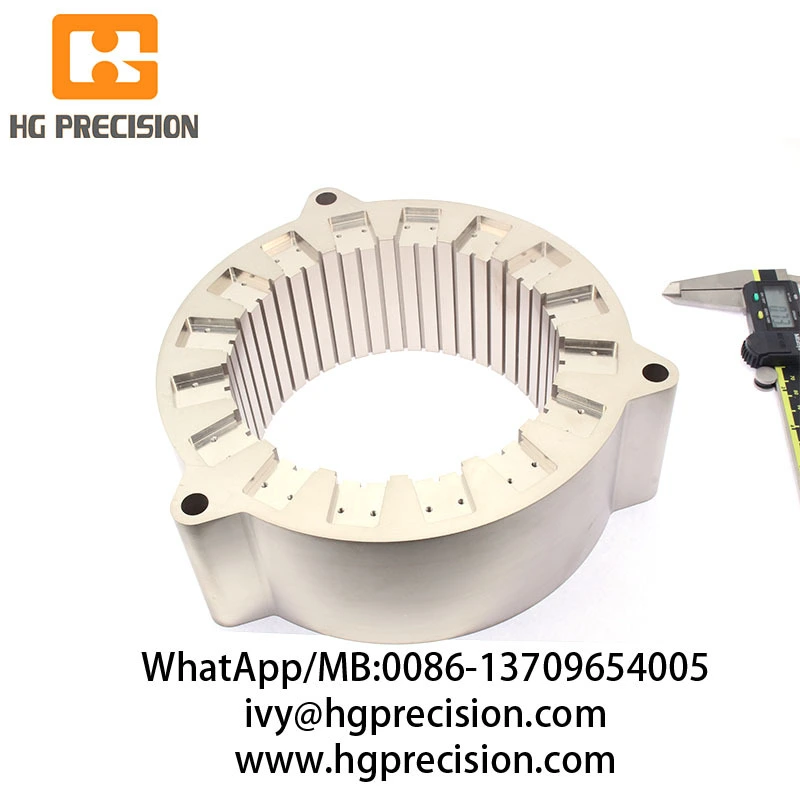

Precision Carbide&HSS Component Manufacture

![]() +86 13709654005

+86 13709654005 ![]() ivy@hg-jingmi.com

ivy@hg-jingmi.com

Precision Wire Cutting Machinery Parts

Precision Wire Cutting Machinery Parts

Product name: EDM Wire Cutting High Precision Mold Parts

1 mold name: mold core insert and punch

2. Material using : imported SKD11,SKH9,Elmax,Viking, or others

3. Size : According customer requirement

4 Processing: grinding, EDM, WEDM, milling, CNC

5. Hardness: 50-65 HRC

6. EDM Precision: within 0.005mm

7. Surface Grinding Precision :within0.005m

8. Surface Roughness for EDM reach to Ra0.1 even mirror surface

9 Angle Clearness<0.05

10. OEM and ODM service: Available

11 MOQ:1 PC acceptable

12. Packing way: Plastic bag

Advantage

1. 60 professional and skilled technicians and 10 master of optical profile grinding ,CNC milling, mirror EDM, wire EDM.

2. our process skills are be industry leadership in mold machining field such as EDM and PG optical profile grinding.

3. HG Precision Mold specialize in precision mold punch and die, non-standard parts , precision progressive stamp mold and precision plastic mold part, drawing mold parts and fine blanking mold parts

4.HG Precision Mold provide advanced R&D service and experienced engineer ,your inquire would get prompt responses within 24 hours.

5. High Speed CNC milling machines mainly make the electrodes and precise cubic curve product, machining variety of precision parts own excellent effect.

6. High Precision Swiss Houser Jig Grinder machines mainly make the parts within 0.005mm.

7. Sodick EDM machines make us possible to ensure EDM accuracy within 0.005mm. For special parts surface roughness, HG Precision Components could handle the Sodick EDM machines, which reach to from Ra 0.15 to mirror surface.

8. Sodick and Seibu wire-cutting EDM, Sodick oil cutting EDM machines, linear motor drive, with newly narrow-gap discharge circuit, ensure accuracy within 0.005mm, flatness, verticality, and linearity within 0.002mm.

9. ISO 9001:2000 system verified and operated.

10. Quick response and timely delivery

11. We have 8 set of high precision EDM machines, the capacity can 1pcs but also mass production for you, also the CNC equipment is over 5sets. Can meet the urgent schedule at short time.

Quality Guarantee

Using dimensional and optical inspection equipment, HG Precision Components ensures that the tolerance and dimensional integrity of each part remains uncompromised.

HG Precision Components operate ISO 9001:2008 system, committing to continuous process improvement eliminating variability and inconsistency within the manufacturing process.

Applying quality tools CPK control key point and key size.

HG Precise Components dedicates to develop long-term relation with customer through reliable quality; and be a truth worthy strategic partner.